Advantages of the Merkle Batch Charger

- Merkle’s Batch Chargers are customizable to each unique operation.

- We build Chargers to best suit needs with simplicity and reliability.

- Our Batch Chargers are durable, long-lasting due to its robust design.

- We combine the very latest technology and materials available to create Chargers that can easily be adjusted to meet changing furnace and production requirements.

Advantages of the Merkle Twin/Coupled Charger

Designed for doghouse widths from 6-14 meters, our twin/coupled machine is comparable to having two independent, single pan machines coupled together. The Twin/Coupled Charger allows you to pull one unit back if there is a batch plant malfunction (with insufficient batch for both units) or for parts replacement or maintenance. The remaining unit will continue to charge the furnace, minimizing furnace upset associated with a break in batch charging.

- Machine Alignment

The two halves of a Twin/Coupled Charger are mechanically connected to form a single, rigid assembly, simplifying alignment. - Synchronization of Pans

The mechanical coupling of Charger halves guarantees pan synchronization. If desired, the operator can disconnect the center coupling to operate pans independently, or pans can be operated up to 180 degrees out of phase relative to each other. - Auxiliary Drive on Standby

Two motor/speed reducer assemblies service an entire charging system, normally with only one in operation at a time. Consequently, the remaining drive is on the line as a spare without altering the Charger position. Drive changeover can be accomplished in minutes. - Electrical Installation

Only two motors require electrical connection to the facility, and synchronizers are not required.

Advantages of the Merkle Modular Charger

The newest in our line of state-of-the-art Blanket Batch Chargers offers impressive solutions to many of your charging challenges. A small version of our Single Pan machine, the Modular Charger can be made in widths from 1-2 meters, to be used for very small furnace openings, or in sets to accommodate any doghouse application.

- Easier Handling

Manageable modules move into and out of position more easily than with the larger machines. - Programming of Batch Distribution

With an electronic synchronizer, multiple units can be configured to produce feed profiles unavailable with wider units. Pan separations of 25mm give the modular unit the ability to retain batch log formation that is otherwise available only on larger machines. - Lower Impact of Inactive Machine

Each unit is small so that removal of one module from service has temporary minor impact on profile and negligible effect on batch feed rate.

Additional Information

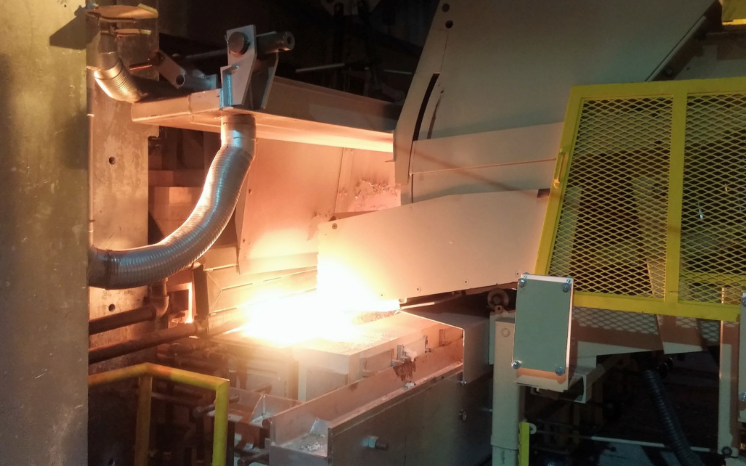

At Merkle International, our primary goal is to provide the glass industry with the best in customized equipment. The Merkle Charger gives you a wider range of batch feed capabilities than ever before. We provide the charger that is best suited to your operation, carefully considering your installation and service requirements.

We build chargers to suit your needs with the simplicity, durability and reliability you have come to expect from us. When complete, we run your machine through its shop trials. Only then is it ready for your inspection.

Merkle provides supervision for both installation and commissioning of your charger. Our representative will work with your personnel to reassemble the charger and set it up to suit your method of operation. A separate visit is made toward the end of furnace heat-up to position the Charger and make final adjustments. Instruction in maintenance and operation is conducted during these visits.

We are always available to discuss or answer questions by telephone, FAX or e-mail. For those problems, which require a site visit, arrangements will be made quickly. We also offer an extended maintenance agreement, which includes periodic inspection, assessment of the Charger, and review with your maintenance personnel, covering the features, functions and maintenance of the Charger.

Merkle’s pneumatic sand seal system gets high marks from production and maintenance personnel. This sand seal works efficiently to prevent batch from escaping underneath the wiper bar, keeping the machine and the floor clean.

We combine the very latest technology and materials available to create Chargers that can be easily-adjusted to meet changing furnace and production requirements. In a few minutes or less:

- Pan travel (stroke) can be adjusted with common tools to suit varying feed rates or blanket requirements.

- Adjustments for pan angle and elevation can be made quickly during operation, using controls conveniently located on the Charger.

- Blanket thickness and profile are easily changed by adjusting the position of individual gates with a simple ratchet mechanism at the side of the Charger.

- Monitoring these adjustments is made easy by the convenient location of indicators for pan angle, pan elevation and gate positions.