Advantages of the Merkle’s Tin Bath Roof

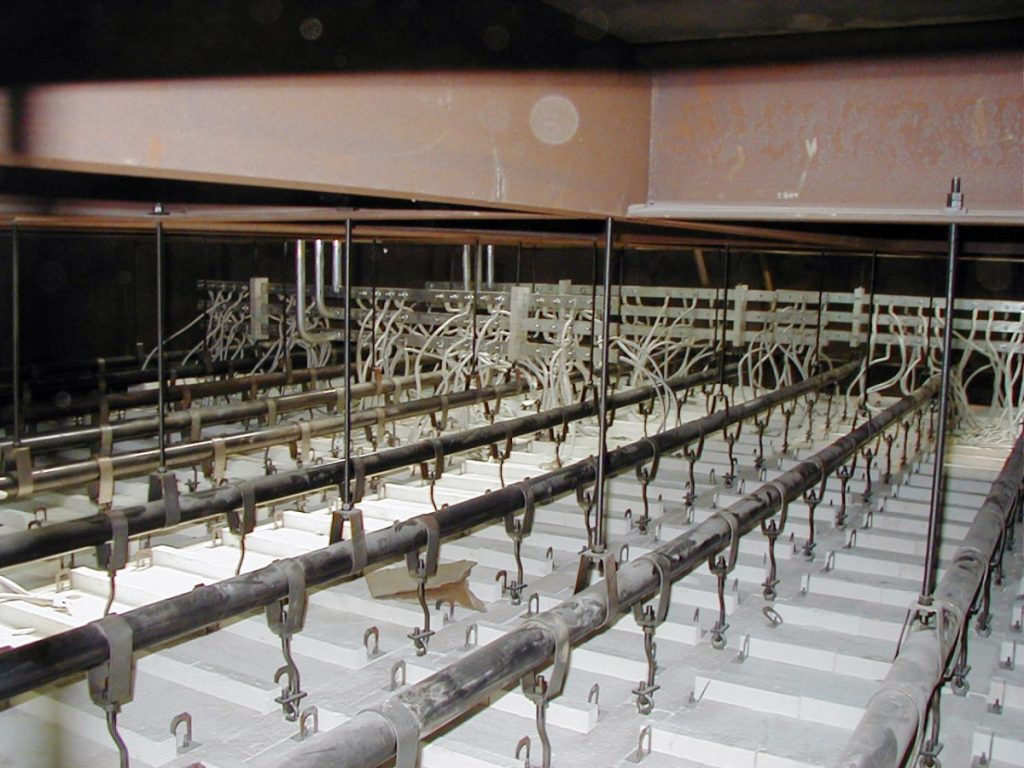

- The Merkle Bath Roof is a completed design, including the following: refractory design, metallic hanger design, electrical distribution system, sidewall and casing design.

- Our Tin Bath Roof has large roof modules leading to no broken element modules and less tin drip creating a higher glass quality for our customers.

- Mechanically assembled Merkle modules aid in the ease of installation and replacement of Tin Bath Roof.

- Faster installation than competing roofs, several customers have reported up to 1 week quicker.

Additional Information

Merkle International brought its first Tin Bath Roof to market in the early 1970s. This new flat roof system was introduced to solve the problem in the early float installations of defects resulting from condensed tin vapors that collected and dripped onto the upper surface of the glass.

In the early 1990s, Merkle expanded its scope of supply beyond the suspended roof system, to include the electrical distribution system and, where appropriate, the upper steel casing. As part of this change, Merkle looked closely at its entire scope of supply, and found ways to make improvements to the three major areas.

The glass manufacturing industry has improved the float process and expanded its use. Merkle International has contributed to the improvement and expansion, using its experience and knowledge of tin bath operating to make improvements to and further develop its suspended bath roof system. Some of those improvements and developments are:

- Mechanical assembly of the modules to tie the hot sillimanite to the IFB, similar to the original module construction by Merkle. The mechanically fastened module provides positive attachment of the refractory layers, and can be supplied at essentially the same cost as the mortared-style construction.

- Redesign of the refractory hanger tiles and hanger metallic to provide a roof system that further reduces heat loss by an average 20%. This system is suitable for the higher temperatures in the tin baths producing specialty float glasses.

Side-element installation to allow change of damaged heating elements during operation. Some customers have included features for future application of side-heating elements in the recent roof installations. Merkle has a removable side-element concept which utilizes the side-seal area for installation. This is helpful on older roofs when heating capacity has been reduced to aging and mechanical damage to the roof elements.

Refractory and Suspension Improvements

- The refractory system was modified to reduce joint length in the roof as far as practicable by widening the module and lengthening the refractory hanger.

- The wider module means more material in the element module between the outer element holes and the edge of the module, providing a stronger shape that is more resistant to breakage.

- The refractory hanger shape was changed to allow a suspension casting to clasp the head of the shape from the outside (instead of being buried inside near the hot face).

- The suspension metallic is a simple two-part assembly; the high temperature alloy casting engages the hanger refractory below the cold face of the insulation, and the mild steel suspension rod connects to the casting above the top of the insulation. The secondary suspension system comprises round pipe hung from the upper casing with pipe hangers.

Electrical Distribution System Improvements

The electrical distribution system has been simplified by positioning the bus bars parallel to the glass flow. This reduces the amount of cabling required to connect all the elements. The bus bars are connected the power source with a secondary cable clamps made of either chrome-copper or aluminum alloy.

Upper Bath Casing Improvements

The upper bath casing was redesigned to allow disassembly of the casing sections for easier shipping. Key to this change is the bracing used to help the sides of the casing sections remain perpendicular to the top –even as the bath is heated up.

Complementary Products

Merkle offers two products that are used in combination with the tin bath roof and include:

- Merkle Bay-0-Seal mates to the entrance of the tin bath and provides an excellent seal.

- Merkle’s has a unique dross box hood design. The dross box fits between the exit lintel and the cooling lehr.