Advantages of Merkle’s Strut-Air System

- Because there is a flat, sloped surface just above the glass, the melting process starts immediately, as the batch collects the radiant heat reflected from this surface. The design allows for various refractory materials to be used, depending on the type of glass being melted.

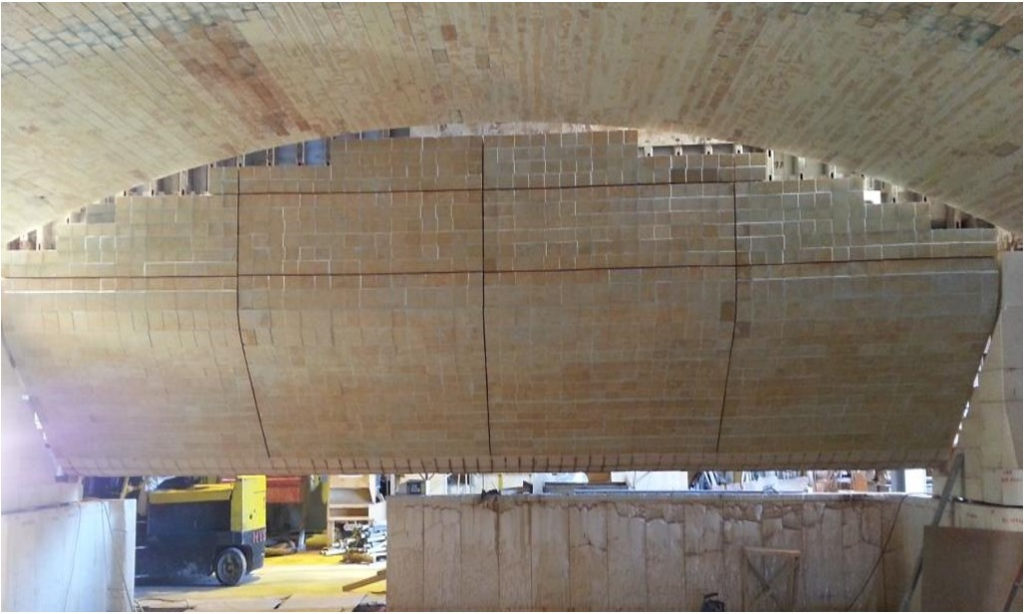

- The main feature of the Strut-Air system is suspension of a simple refractory wall by a series of moveable, fabricated structural tubes. These tubes not only provide support but also carry cooling air directly to the tie-back and support castings.

- The design is versatile. The walls have been constructed for doghouses as small as 1.2 meters and as large as 12.2 meters wide.

- Installation is simple and accurate. Strut-Air requires as few as two parent refractory shapes, which simplifies installation and helps insure proper fit during assembly.

- Cooling air in the Strut-Air system is pressurized, to prevent refractory “rat-holing” from the corrosive furnace atmosphere.

- For smaller furnace/doghouse applications, the support steel can be fabricated as a single frame, which functions as both support and conduit for cooling air.

- The design of the individual refractory shapes allows refractory expansion on this unitized steel frame.

Advantages of Strut-Air Over the Jack Arch/and/or Conventional Construction:

- With the Strut-Air system, various angles can be incorporated into the sloping toe. This opens up the doghouse and improves radiant and reflective heat transfer. Thus, the batch glazes more quickly, which reduces the carryover of batch dust into the checkers.

- Because the Strut-Air tubes are included in the scope of supply, initial material costs for the Strut-Air system may be slightly more than those for jack or sprung arch construction. Labor costs, however, are generally less because the installation of the Strut-Air system is simpler.

- When a furnace is rebuilt, the Strut-Air tubes are reused. Thus, for furnace rebuilds, the replacement of refractory, castings, insulation, and sheet metal is less costly than replacing large blocks of fused AZS material.

- Add up all of the benefits–cost savings, the higher melting efficiency of the batch in the doghouse, and the reduced clogging of the checkers–and the Strut-Air system is clearly superior to jack and sprung arch construction.

Additional Information

Once a furnace that could endure an entire decade of glass making was little more than a wish. Today, furnaces routinely operate through campaigns of 14-15 years. The refractory spanning the charge opening can be the weak point of a good furnace. Feeder end wall designs that were good enough for yesterday’s furnaces could deteriorate before the rest of today’s furnace needs rebuilding. Merkle’s unique Strut-Air refractory system is specifically designed to provide a feeder end wall that will both improve production efficiency and complement the long-campaign furnace.

Why Strut-Air? The doghouse on a modern glass melting furnace needs to be more than just an opening in the side of the furnace through which the batch is introduced. With Strut-Air walls, the doghouse becomes a dynamic part of the glass melting process.

Insulated Strut-Air is the perfect way to keep thermal energy under wraps. Years ago, glass manufacturers issued Merkle a challenge: Design an insulated Strut-Air system to reduce the amount of energy needed to produce each ton of glass. After experiments with several different materials and thicknesses, Merkle learned that, for most feeder wall applications, 25mm of ceramic fiber board is the optimum amount of insulation. 25mm of ceramic fiber board can reduce heat loss by more than half, from 2350 to 1080 BTUs per square foot.

Since 1986, Merkle has been insulating Strut-Air walls with either 25 or 50 mm of insulation. As energy costs, have increased the use of 50mm-thick insulation has become justifiable. Merkle has adopted this as our standard. Depending on current energy costs, Merkle’s Strut-Air insulation package can pay for itself in 9-18 months, and save more than 10 times its original cost over a 10-year campaign.